3D printing, a hobby to some, a new industrial revolution for others. The latter is how DeFacto, a local design agency founded in Beijing in 2015, views 3D printed products and design. DeFacto, short for “Design Factory,” focuses on new technologies in order to find ways to solve real world, impactful problems such as sustainability in architectural design. The company’s three co-founders, Leandro Rolon, David Doepel, and Ami Nigam began their company by providing 3D printing public workshops on the weekends but have since then focused their energy on creating 3D printed products for various clientele. We recently sat down with Leandro Rolon and David Doepel, two of the company’s co-founders, to discuss the company’s recent work and future.

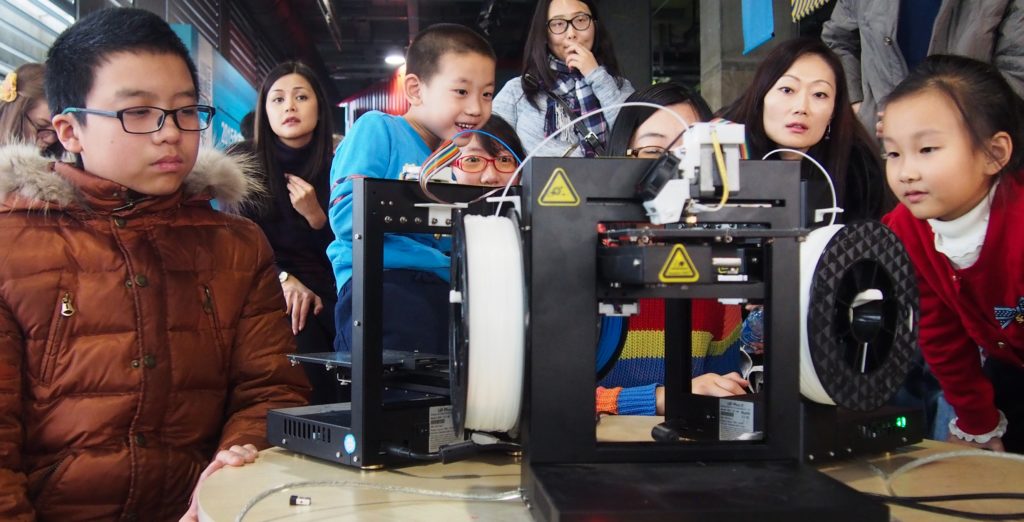

For parents in Beijing, who have already witnessed the introduction of 3D printers into their child’s schools, Rolon believes it is important to know that 3D printing is more than just an extracurricular or a means to an end. “[Parents] see [3D printing] as a hobby […] but there’s a lot more to it. The promise of 3D printing is it’s like a new industrial revolution, it’s about the change the way we do a lot of businesses and how we make things across the world.” Rolon believes that parents should understand the deeper meaning and goals behind the technology rather than focus solely on the potential material benefits that the technology will bring.

Students and adults inspecting a 3D printer at one of DeFacto’s Demo Workshops.

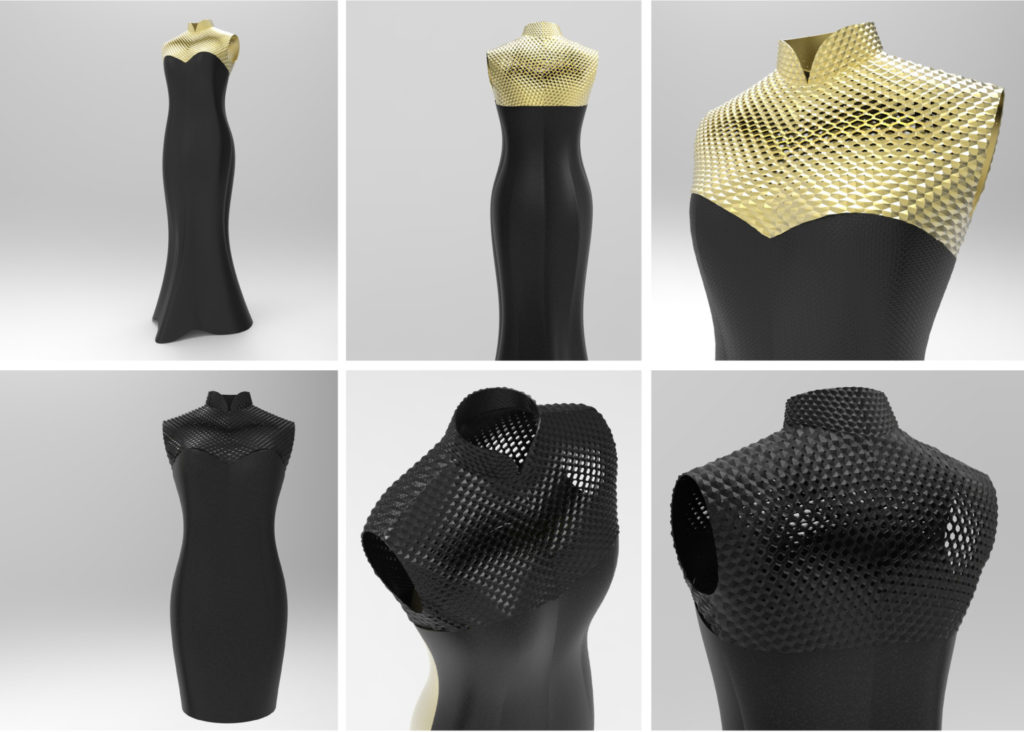

Since the group ceased their weekly workshops, now providing only on-demand workshops for groups of 10-15 at a time, their projects have covered a seemingly random range of industries. The projects have included setting a Guinness World Record for the largest 3D printed structure, creating 3D printed fashion pieces, and 3D printing pieces using chocolate. However, for the group the products and outcomes of their 3D prints do not stand as the most important aspects of their company. Instead the company sees 3D printing as a tool for creating more sustainable, forward-thinking, and smart products aimed at shaping the world in a positive way.

When clients first reach out to DeFacto with a project idea or problem to solve, Rolon says that the team first thinks deeply about the issue at hand rather than the tool that they should use to solve it. While currently the company has used 3D printers as a major method of problem solving, they have also used computers, pens, paper, glue sticks, and zip ties.

The company focuses on design thinking in creating their products. “Design on the other hand, to us, is about the act of solving problems in a beautiful way. […] It is important to note that good designs can also and should also be about beauty but more so in terms of functionality and use of materials and resources.” Rolon reflected that often times clients or individuals will seek advice from the company about a prospective 3D printing project. However, through consultation with the client it becomes apparent that 3D printing may not be the best option for their particular needs. In these cases Rolon and his team will recommend other methods of carrying out the project and help to try and find alternative solutions.

According to Rolon, experimentation and cross-project work represent the method and the madness of the company. Rolon explained that while their project areas are widespread the products and byproducts of their work on one project have helped to inform work on a project in an unrelated field. While cleaning up their work making silicone molds for a food-related project, the team realized that the silicone they pulled from the edge of the mixing tub came off textured. From this they realized they could make textured silicone in their fashion projects.

DeFacto’s Queen Bee dress, which was the centerpiece for a display in Parkview Green for Beijing Design Week 2015.

The creators also emphasize zero-waste, modularity, and problem solving in their work. For instance, before taking on the Guinness World Record, Rolon said the team had one condition: that the piece had to be zero-waste from start to finish. The team coordinated with a host of organizations including RISE Education, an education group focused on English learning for kids in China, to create the Rise Pavilion. The Pavilion not only set a Guinness World Record, but DeFacto and Rise Education also integrated the project into RISE’s annual competition that asks kids to imagine the future. In 2016, the competition asked students to imagine the future of living and the top student projects were displayed in the Pavilion via QR codes that were 3D printed into blocks throughout the structure. After the team completed the Guinness World Record project, each student took home a building block to imagine the block’s up-cycling potential.

Rolon and Doepel expressed interest in providing educational tools and workshops in the future, but for now they are focused on establishing relationships with current and potential clientele. As for now, the company seems fully prepared to both ride and shape the wave of the new 3D printing movement.

For more information, or to get in touch with DeFacto, interested parties can visit their website defactobeijing.com, follow the group on wechat at defactobeijing, or email them at info@defactobeijing.com.